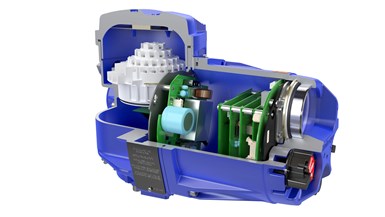

Flowserve Launches New Limitorque QX Series B Quarter-Turn Smart Electric Actuator

New actuator streamlines user experience and accelerates commissioning.

#actuators #VMAnews #automation

Flowserve Corporation, a provider of flow control products and services for the global infrastructure markets, announced the release of the new Limitorque QX Series B (QXb) quarter-turn smart electric actuator.

“The Limitorque QXb electric actuator provides unmatched reliability and precision while lowering the cost of ownership in a range of demanding applications,” said Mark Stone, global product leader – electric actuation, Flowserve. “This next-generation device builds on the proven state-of-the-art Limitorque MX actuator platform to provide all the user-preferred features in a quarter-turn, smart actuator package, plus connectivity with the Flowserve Flowsync App.

“Flowserve improved the interface to streamline the user experience and accelerate commissioning by as much as 50 percent. In addition, the QXb actuator enables backward compatibility with older QX actuators, via a conversion kit, which helps reduce costs and provides future-proofing.”

The Limitorque QXb actuator is designed for versatility in demanding applications within the following industries:

- Oil and gas: upstream and midstream (choke, isolation and control valves)

- Fresh water and wastewater: isolation, air scour and control valves

- Commercial power: wind energy (cooling water for offshore high-voltage, direct current [HVDC] converter platforms)

- Chemical

- General industries

Reliable flow control automation solutions are crucial for sustainable operations. Flowserve engineered the QXb actuator to maximize dependability and efficiency while enabling the transition to a low-carbon future. Along with a streamlined user experience and advanced diagnostics, it’s designed to support customer initiatives to consume fewer resources.

A large, high-resolution liquid crystal display (LCD) with adaptive brightness control provides improved legibility as well as real-time actuator status and valve position. Its IP68-rated double-sealed enclosure and non-intrusive control knobs eliminate the risk of water or dust ingress for improved reliability; this design also removes the need for a heater. Increased precision is also achieved with 0.1 percent positioning accuracy.

Learn more about the actuator and its capabilities.

RELATED CONTENT

-

An Interview with VMA's New Board Chairman

At VMA鈥檚 83rd Annual Meeting, Ron Warren, President and COO of Bray International Inc., was elected the board chairman of VMA for the next year.

-

Using Additive Manufacturing for Valve Repairs Across the Globe

Printing components on-site will allow for faster repairs and parts replacement for critical applications.

-

Valves in Oxygen Service

In his presentation at VMA鈥檚 2017 Technical Seminar, Kurt Larson, a process control engineer for Air Products, spoke about the inherent danger of the oxygen production business and how it is particularly important for end users and valve manufacturers to work closely together.

Unloading large gate valve.jpg;maxWidth=214)