Podcast Episode Explores 3D Printed Valve Components

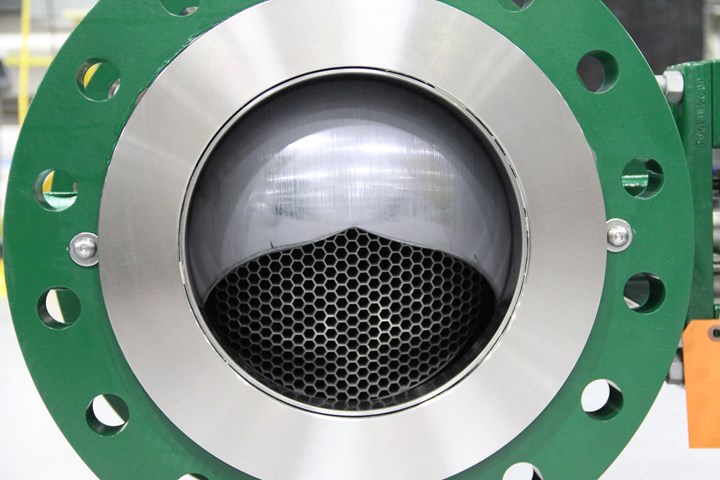

Fisher Cavitrol Hex trim from Emerson divides fluid flow using geometry produced by additive manufacturing.

#components #VMAnews

The Cool Parts Show, the video podcast produced by the editorial team from Additive Manufacturing magazine, just launched its latest episode featuring Emerson’s Fisher Cavitrol hex trim. They discuss how this product was originally made by brazing multiple pieces of tubing together to create a honeycomb shape, preventing cavitation and stabilizing pressure. The product was eventually discontinued, but additive manufacturing has made it possible to produce this part again much more easily than before.

Fisher Cavitrol hex trim divides fluid flow into parallel streams to prevent cavitation of pipes.

Photo Credit: Emerson

Pete Zelenski and Stephanie Hendrixson spoke with Brandon Bell, product marketing manager from Fisher (an Emerson brand), about the manufacture of this product.

You can also read more about this product and other valve manufacturers that have employed 3D printing in this article from our Summer 2022 issue.

RELATED CONTENT

-

SAMSON Awarded Certification for Additively Manufactured Pressure Equipment

Major milestone for valve engineering and manufacturing of pressure equipment.

-

In the Air: Wireless Trends in Smart Pneumatics

In today鈥檚 wireless world it鈥檚 no surprise that automation and manufacturing spaces have embraced鈥攁nd sought out鈥攖he connectivity and convenience that wireless technologies offer.

-

Westinghouse鈥檚 Additive Manufacturing Innovation Improves Safety and Efficiency in Operating Nuclear Reactors

This industry-first milestone increases bottom nozzle debris resistance from 65% to 96%.

Unloading large gate valve.jpg;maxWidth=214)